CO₂ is not only a climate killer, but also a raw material

The greenhouse gas carbon dioxide (CO₂) is not only a climate killer, but also a raw material from which chemical precursors and fuels can be produced. By recovering CO₂ from the atmosphere using industrial methods, the process can also contribute to climate protection. However, it remains very energy-intensive. ZHAW researchers have now developed a material that makes this process more energy-efficient.

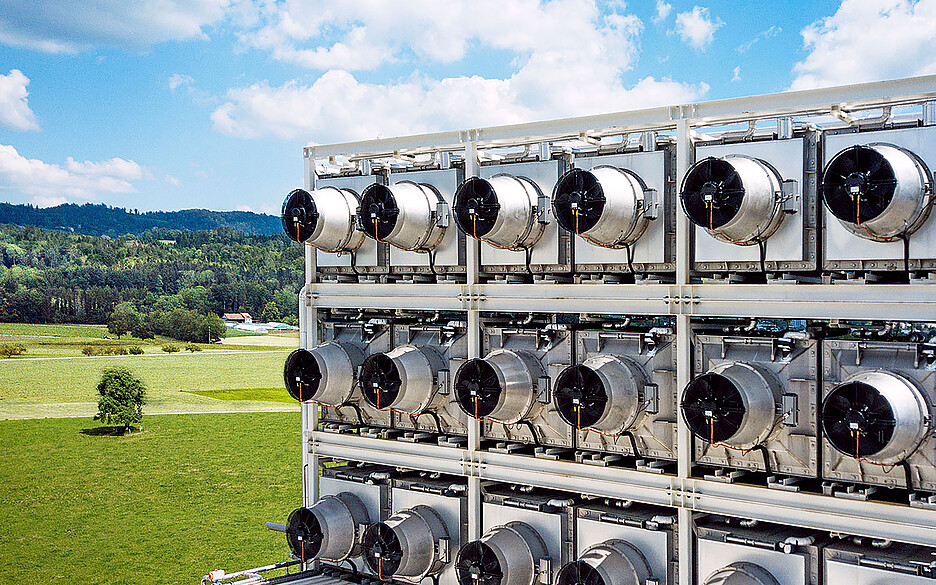

In order to limit global warming and achieve the stated climate objectives, a drastic reduction in CO₂ emissions alone will not be enough. Instead, it will also be necessary to remove as much CO₂ as possible from the atmosphere. Various technologies have already been developed that allow for CO₂ to be captured from both air and water. CO₂ from power plant waste gas flows, for example, can be treated using a kind of chemical shower. CO₂ can also be separated on a selective basis using membranes, while another possibility is to extract the greenhouse gas directly from the air (direct air capture).

However, all of the methods require energy or negatively impact a power plant’s energy output. Nobutaka Maeda, a research associate at the ZHAW Institute of Materials and Process Engineering (IMPE), has developed a hybrid material that makes the direct air capture process significantly more energy-efficient. In this process, surrounding air is drawn in and flows through a kind of filter that is coated with a CO₂ absorbing material. Heating the filter to a temperature of up to 100 degrees Celsius causes the CO₂ molecules to break free, meaning the CO₂ can be separated. “With the help of the IMPE-Cap, the CO₂ molecules already break free at 50 degrees Celsius,” explains Daniel Meier, Head of the Laboratory of Process Engineering at the IMPE. As such, the process of industrial CO₂ recovery not only reduces operating costs, but also saves a great deal of energy. “Our goal is to contribute to the recovery and use of CO₂ in this way,” says Daniel Meier. Once the CO₂ has been recovered from the air, it can be processed further in a multitude of ways.

CO₂ as a base material for fuel and the chemical industry

In 2020, approximately 36 gigatonnes of CO₂ was emitted worldwide. There is thus enormous amounts of it in the atmosphere. “This CO₂ either has to be stored in a suitable geological formation or used as a valuable raw material,” explains Daniel Meier, citing the production of fuels or use as a chemical precursor as examples. “For instance, hydrogen can be used to produce the fuel methanol,” says Daniel Meier. One use of methanol is as an additive in petrol and diesel. And it can also be used as a chemical precursor, for example during the production of plastics. There is now also a range of requirements for the recovery of CO₂. By 2030, for example, waste incineration plants will be obliged to directly capture part of the CO₂ they produce.

“We need to move away from the idea of CO₂ being something negative and instead use it as a raw material that can be utilised in a multitude of ways,” Meier argues. Scientists around the world are currently working intensely on this. The IMPE-Cap could therefore be a building block for making the recovery of CO₂ more energy-efficient. “In principle, the most efficient way to capture CO₂ is directly during the combustion process, for example at power plants and waste incineration plants,” emphasises Daniel Meier. The ideal outcome would be a cycle in which the emitted CO₂ is captured and then reused as a base material in many different areas. The capturing and recycling of CO₂ can thus ultimately make an important contribution to climate protection.

0 Comments

Be the First to Comment!