Carbon-fibre-reinforced concrete panels: Reusable, filigree and flexible

Filigree carbon concrete panels developed by the ZHAW are now being used in building construction for the first time. This innovation allows for significant CO2 and material savings and provides the basis for a flexible system with components that can be reused in a manner reminiscent of Lego bricks.

Designing, constructing and planning buildings on a computer is nothing new. For the first time, however, filigree yet resilient prefabricated elements are now available for building construction: carbon-fibre-reinforced concrete panels. “Our carbon concrete construction system works in a similar way to Lego, but like a modern version of it, with customised components,” explains ZHAW researcher Josef Kurath, who has developed the flexible construction method. It offers a number of advantages, as illustrated by a 120-square-metre pavilion in Winterthur, which was built using the ZHAW’s flexible construction system.

This so-called innovation lab will open its doors in spring 2024 and will serve as an information and event venue for sustainable construction. “It is the first time that this construction principle has been used in the field of building construction. The innovative lightweight concrete construction method opens up completely new possibilities, for example with respect to the integration of building technology and not least the design,” says Alexis Ringli, supervising architect and a lecturer at the Institute of Constructive Design at the School of Architecture, Design and Civil Engineering.

“The lightweight concrete construction method opens up completely new opportunities.”

Flexible modular system for building construction

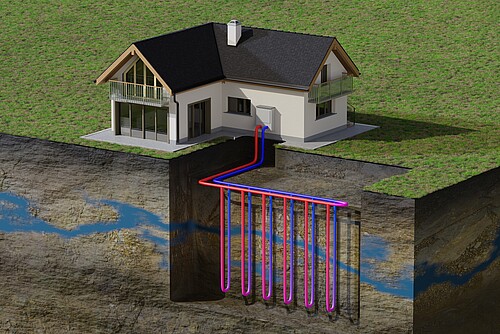

The carbon concrete panels used here are manufactured, processed and cut to size in the factory. Using plug-in systems, they can be assembled into structural elements while still in the factory, which means that they can be installed on the construction site in no time at all. “This results in much shorter construction times, which is primarily a benefit for urban construction sites,” says ZHAW Professor Josef Kurath. What's more, buildings can be easily adapted or extended on site. The new pavilion houses an exhibition space, a stage and a small café under its roof. If necessary, the innovation lab could be expanded into a neighbourhood centre. The structural design of the pavilion was already put together with a two-storey, closed building in mind. The city of Winterthur can well imagine that artists’ studios, a party venue or a day nursery could be created here in the future.

Borrowing building components instead of buying them

For the time being, however, the pavilion is to be used as an innovation lab for around ten years. After this time, it will be possible to dismantle the building with little effort and rebuild it at another location. Alternatively, the individual elements may be reused as part of another structure. This is made possible by an innovative sharing model for carbon concrete panels organised by the building materials producer Holcim. “This approach will allow us to keep resources in circulation for longer. There are also many advantages for developers. For example, they no longer have to dismantle buildings, says Clemens Wögerbauer, Head of Commercial & Sustainability at Holcim. While around 90 percent of the concrete is lost when a conventional building is dismantled, the opposite is true for the new construction system: around 90 percent of the materials and added value in the respective components can be reused. This is a significant factor given that cement alone is responsible for 8 percent of global greenhouse gas emissions and Switzerland has one of the highest per capita rates of cement consumption of any country in the world.

Carbon fibres at the heart of the solution

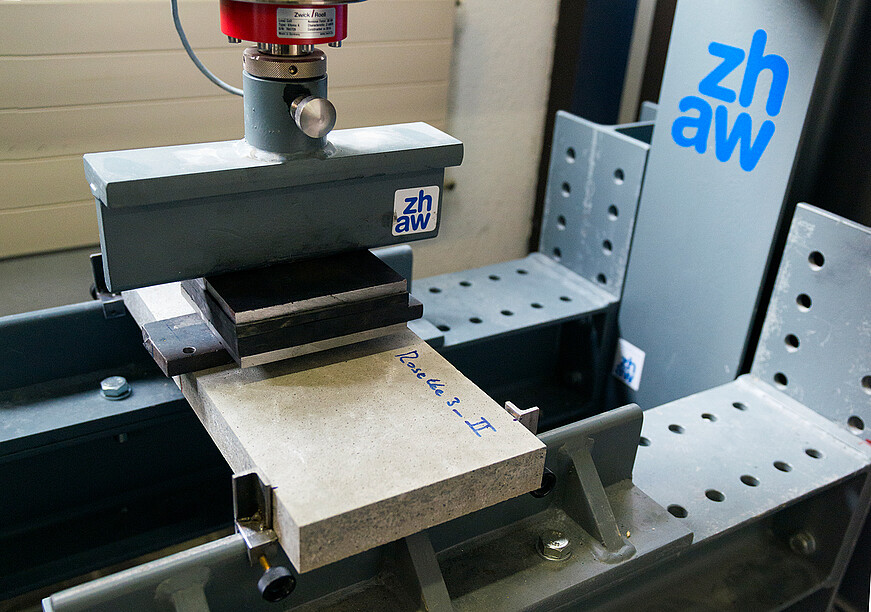

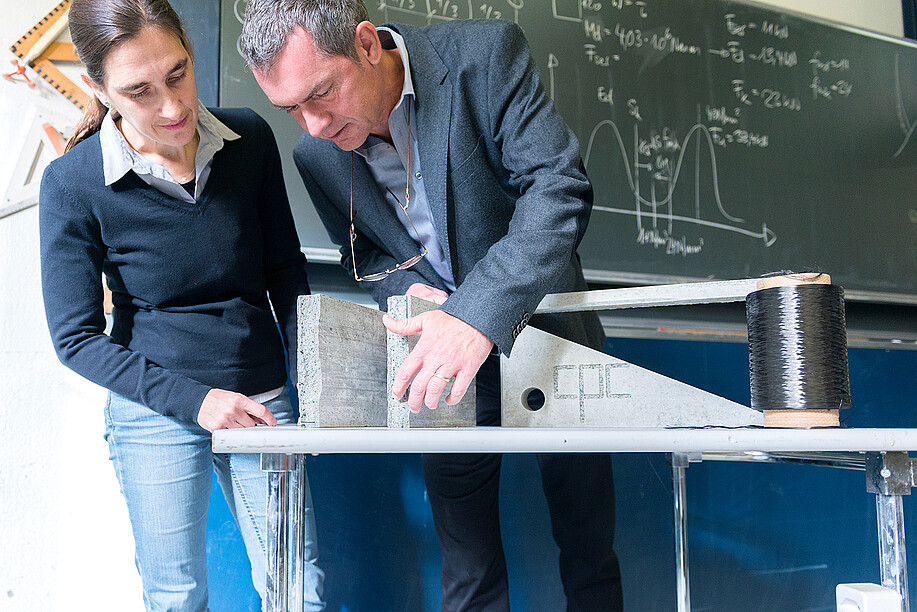

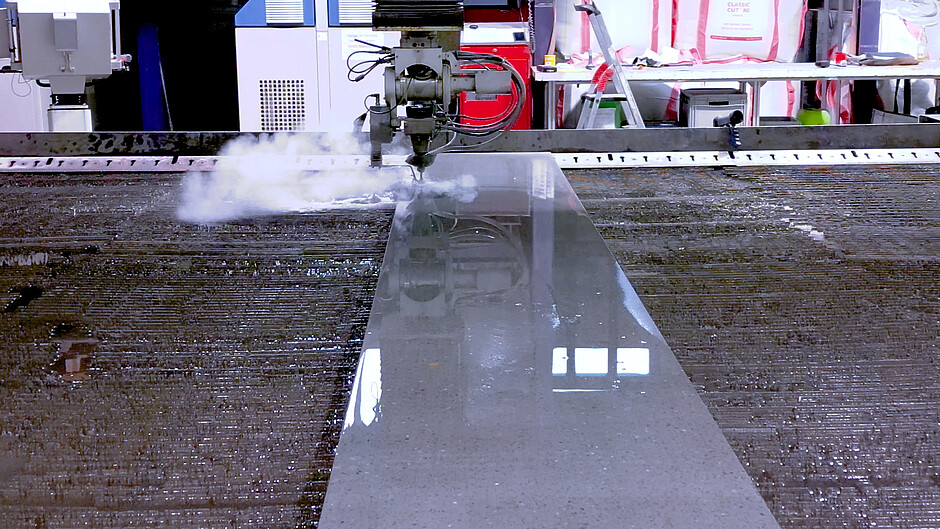

These carbon-reinforced panels are not only reusable and extremely durable, their production is also less damaging to the environment than conventional steel-reinforced concrete. “Thanks to the new lightweight concrete construction method, we are reducing the carbon footprint by a factor of two to four and making material savings of up to 75 percent versus conventional construction methods,” explains Josef Kurath, a ZHAW Professor and the co-founder of the ZHAW spin-off CPC, which developed the filigree yet resilient carbon prestressed concrete (CPC) panels. “Prestressed carbon fibres and concrete complement each other perfectly. While carbon absorbs the tensile forces, concrete absorbs the pressure and transverse forces.” Unlike conventionally reinforced concrete panels, CPC panels do not crack when a load is applied and spring back undamaged. They are also three to four times thinner than conventional materials and yet don’t lose their load-bearing capacity. However, the ZHAW civil engineer believes the greatest potential of the patented CPC panels lies in the fact that they can be industrially manufactured, are customisable and don't rust. “We are the only company anywhere in the world that is able to industrially produce concrete panels that are biaxially prestressed with carbon fibres.”

A building kit to order

The CPC panels are currently being produced at Holcim’s first CPC plant in Germany. The building materials producer has designed the concrete for these innovative construction elements without steel reinforcement. The carbon fibres are being produced by the ZHAW spin-off CPC in Döttingen – in future, it will do so using bio-based carbon from renewable raw materials such as algae and cellulose without the need for any crude oil. With the current infrastructure, around 70,000 square metres of CPC panels can be produced annually, enough for the construction of 14 buildings, with each housing ten flats.

“The patented CPC panels can be industrially manufactured, are customisable and don't rust.”

“In future, the developed panels should also be able to be produced in Switzerland, with the new construction system being able to be widely used in the area of building construction. This Swiss market, in particular, is predestined for this,” says Josef Kurath. There has been a great deal of investment in the development of panel connections for the patented construction system. As these connections exclusively comprise the panels themselves and a conventional mortar, they do not require any adhesive or steel components. According to the ZHAW researcher, research is currently being conducted into ways to optimise sound insulation and fire protection as well as into special structures for an earthquake-proof building core and extensive ceiling connections. “The individual ceiling elements will in future interlock like a zip fastener, meaning that almost endless floors will be possible horizontally – without additional connecting elements.”

0 Comments

Be the First to Comment!